The ATLAS Maximum Demand Control System works intelligently to control a site’s period demand level to pre-set limits.

For those wanting a simpler load control capability, the DIN rail mountable B867 Over-Current Protection Unit may be suitable.

Custom load control solutions can also be supplied to help protect against circuit and transformer overload.

The ATLAS Maximum Demand Control System works intelligently to control a site’s period demand level to pre-set limits.

For those wanting a simpler load control capability, the DIN rail mountable B867 Over-Current Protection Unit may be suitable.

Custom load control solutions can also be supplied to help protect against circuit and transformer overload.

ATLAS Maximum Demand Control

- Control site electrical demand to contractual supply capacity limits (kW or kVA), or simply to limit energy use at peak cost times.

- Maximum Demand Control based on prediction of period demand.

- Eight load shedding control relays for connection (via suitable contactor or PLC) to warning signals, non-essential equipment, or machinery control systems for example to reduce the load drawn.

- Target demand limit set independently for each 1/2 hour period of each day.

- Selectable relay shed & restore sequence.

- Shed & restore hysteresis to account for load start up values.

The ATLAS Maximum Demand Control system comprises three components:

Electricity meters provide usage information in the form of consumption pulses. For example, the meter may send a pulse after each 10 kWh of energy is consumed.

The ATLAS Load Control logger collects these consumption pulses & calculates a prediction of the Period Demand. If the predicted period demand exceeds the preset target level, the 8 control relays will be activated as required in sequence to reduce the site load and hence the predicted period demand.

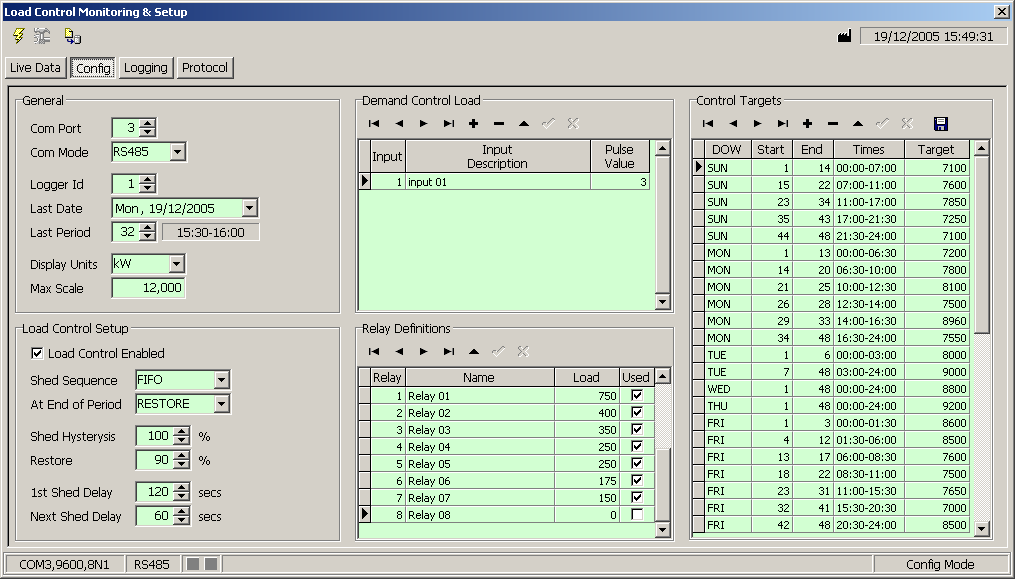

The target period demand level and other control parameters are set via the ATLAS Maximum Demand system software. Once configured, the ATLAS Load Control Logger operates independently of the system software to keep your site period demand within your agreed supply capacity, or target limits.

The LCU continuously monitors the predicted demand level and activates the control relays as necessary when a breach of the target demand is predicted.

The ATLAS Demand Control system software can be left permanently running as a visual display of demand level or simply used as necessary to update the control parameters.

ATLAS Maximum Demand Control:

- Control site electrical demand to contractual supply capacity limits (kW or kVA), or simply to limit energy use at peak cost times.

- Maximum Demand Control based on prediction of period demand.

- Eight load shedding control relays for connection (via suitable contactor or PLC) to warning signals, non-essential equipment, or machinery control systems for example to reduce the load drawn.

- Target demand limit set independently for each 1/2 hour period of each day.

- Selectable relay shed & restore sequence.

- Shed & restore hysteresis to account for load start up values.

The ATLAS Maximum Demand Control system comprises three components:

Electricity meters provide usage information in the form of consumption pulses. For example, the meter may send a pulse after each 10 kWh of energy is consumed.

The ATLAS Load Control logger collects these consumption pulses & calculates a prediction of the Period Demand. If the predicted period demand exceeds the preset target level, the 8 control relays will be activated as required in sequence to reduce the site load and hence the predicted period demand.

The target period demand level and other control parameters are set via the ATLAS Maximum Demand system software. Once configured, the ATLAS Load Control Logger operates independently of the system software to keep your site period demand within your agreed supply capacity, or target limits.

The LCU continuously monitors the predicted demand level and activates the control relays as necessary when a breach of the target demand is predicted.

The ATLAS Demand Control system software can be left permanently running as a visual display of demand level or simply used as necessary to update the control parameters.

Over Current Protection

For those requiring a simple automated load control device, the DIN rail mountable B867 over current protection unit may be suitable.

- DIN rail mounted Over Current Protection.

- Protect circuits from overload to prevent damage or fuse/breaker activation.

- Load limit set to between 20% to 120% of nominal current.

- Single and three phase versions available.

- Operating time 2.5s at 2% over current limit but 0.1s if load hits 200% of limit.

- Single pole change over relay output (double pole option on single phase).

- Optional ‘release’ timer prevents reinstatement of tripped relay for set period.

Available in single or three phase versions, the B867 over-current device continuously monitors the ac current either directly (up to 5A) or via current transformers (for circuit currents >5A) and trips an internal relay when a preset current limit is breached.

The load limit is set via a simple dial to a percentage (between 20% & 120%) of the nominal current.

For example, if 100/5A CTs are used, the load limit may be set between 20% and 120% of 100A.

Over Current Protection

For those requiring a simple automated load control device, the DIN rail mountable B867 over current protection unit may be suitable.

- DIN rail mounted Over Current Protection.

- Protect circuits from overload to prevent damage or fuse/breaker activation.

- Load limit set to between 20% to 120% of nominal current.

- Single and three phase versions available.

- Operating time 2.5s at 2% over current limit but 0.1s if load hits 200% of limit.

- Single pole change over relay output (double pole option on single phase).

- Optional ‘release’ timer prevents reinstatement of tripped relay for set period.

Available in single or three phase versions, the B867 over-current device continuously monitors the ac current either directly (up to 5A) or via current transformers (for circuit currents >5A) and trips an internal relay when a preset current limit is breached.

The load limit is set via a simple dial to a percentage (between 20% & 120%) of the nominal current.

For example, if 100/5A CTs are used, the load limit may be set between 20% and 120% of 100A.