Case Study – Profile Portable Energy Monitor

VAR Services offer a comprehensive Energy, Harmonics and Power Quality Survey service and just as importantly, a range of Power Quality Solutions including the supply and serving of Power Factor Correction equipment, Harmonic Filters and Uninterruptible Power Supplies.

One of their clients, an international business, has several manufacturing locations producing parts for the cleaning of materials and liquids.

One of the UK sites had a concern regarding the level of electricity use and doubted the accuracy of electricity bills received. The site is supplied by two 1000 kVA transformers and consideration was being given to the installation of power factor correction equipment to help reduce the energy costs. One of the transformers supplies a main Low Voltage switchboard where the existing panel power meter was indicating that problems existed.

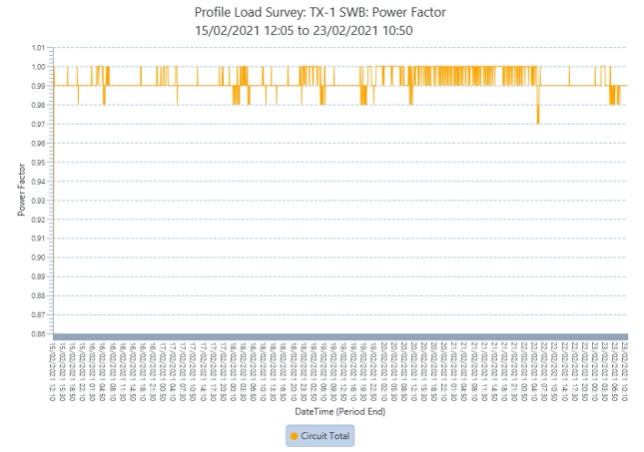

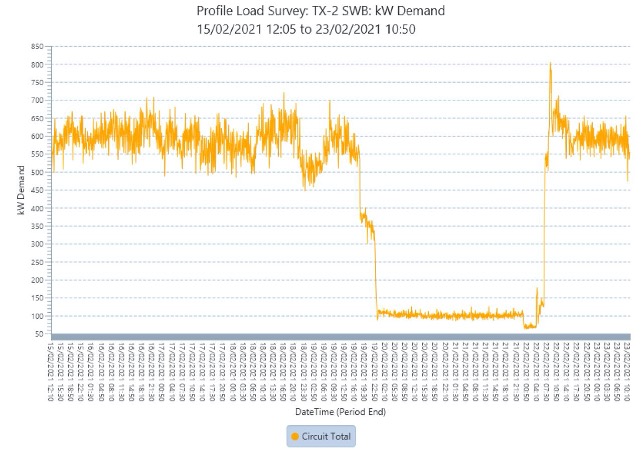

To check the situation and determine whether power factor correction should be considered, a Profile energy monitor was installed on each of the 1000 kVA transformers to record 5-minute demand values over a 7-day period.

Using the ProPower 3 software supplied with the Profile energy loggers, VAR Services produced a report for the client demonstrating that

- TX-1 had a PF of 0.95 lag or better throughout the survey this transformer provides ~45% of site energy

- TX-2 had a PF of 0.97 lag or better throughout the survey this transformer provides ~55% of site energy

A comparison with the information provided by the Profile against the installed meter on TX-2, confirmed that the panel meter was incorrectly installed and thus providing false data to the client.

The Profile energy survey consumption report was scaled with the ProPower 3 software to provide a monthly kWh energy figure, confirming that the electricity bills being received were correct.

The energy survey report also highlighted that during the weekend period a significant amount of energy was being consumed and this did not relate to operation levels. Each transformer had a base load of above 100 kW and the reason for this is now being investigated by the company to assist in their energy reduction programme.

In summary the Profile Energy Monitor surveys provided information that

- Confirmed that the site operating PF was above 0.95 lag, thus not really a problem

- The electricity bills being received from the supplier are correct

- Provided the amount of spare kVA capacity available for additional load on each transformer

- Identified a high out of hours base load, to be investigated with an intention to reduce it and reduce energy use out of hours